În industria producției de poliester, menținerea unor costuri scăzute pentru ca afacerea să rămână profitabilă și competitivă este esențială. Mașinile de poliester sunt echipamentele cheie în această fază a procesului de fabricație. Ele ajută la reducerea costurilor prin îmbunătățirea eficienței, minimizarea deșeurilor și economisirea energiei. Caracteristici care permit economisirea de bani, ajutând producătorii să-și mențină calitatea produselor. Ca furnizori de soluții industriale avansate, Shenzhen Softgem Technology Co Ltd dezvoltă sisteme performante de mașini pentru poliester. Iată modurile specifice în care o mașină de poliester reduce costurile de producție.

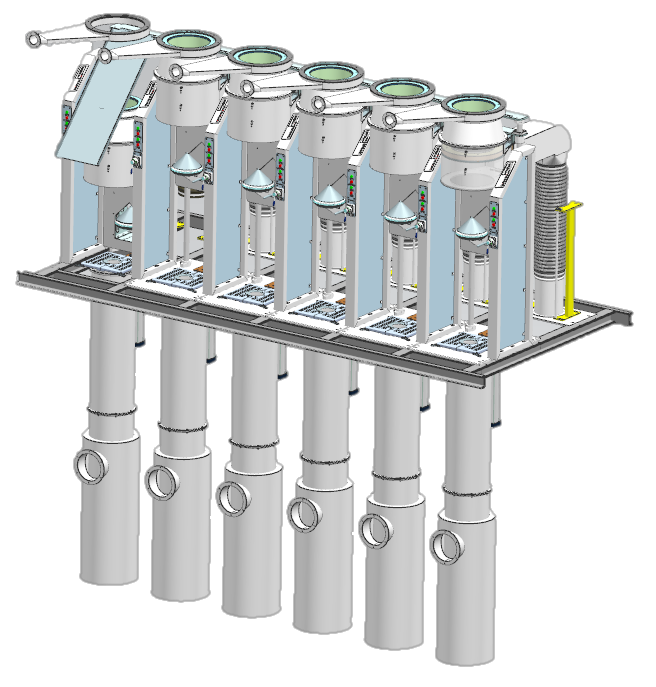

Mașinile pentru poliester realizează reduceri de costuri deoarece accelerează producția. Calificarea costurilor la mașinile mai vechi de poliester includea productivitate redusă și cicluri lungi de producție bazate pe tehnologii inferioare, precum și cicluri de producție intermitente. Provocările ridicate de mașinile rotative și cele în loturi, care folosesc tehnologii vechi, sunt acum minimizate datorită producerii continue și la viteză mare. De exemplu, mașinile pentru poliester au crescut standardul industrial de producție a fibrelor de poliester de la 50-60% la 800-1000 m/min. Astfel de capacități la viteză mare permit trecerea producției de la kilograme la sute de tone, distribuind astfel costurile fixe pe un volum mai mare de producție și reducând semnificativ prețul de vânzare pe tonă de poliester. Competiția prin cost la IPO-ul poliesterului de la Shenzhen Softgem provine din minimizarea costurilor mașinilor pentru poliester prin proiectare modulară. O astfel de configurație sporește, de asemenea, eficiența producției și contribuie la minimizarea costurilor unitare.

Investiția în echipamente eficiente este o cale sigură de a reduce costurile producției de poliester, deoarece o mare parte din costurile de producție sunt atribuibile cheltuielilor cu materiile prime. Echipamentele necalibrate corespunzător și procesele ineficiente de producție sunt principalele cauze ale deșeurilor în producția de poliester. Echipamentele sofisticate pentru producția de poliester utilizează inteligență artificială avansată pentru a determina parametri cheie ai producției, cum ar fi punctul de topire, parametrii de extrudare și monitorizarea tensiunii, în timp real. De exemplu, echipamentele avansate pentru producția de poliester pot identifica deșeurile de poliester generate de procese de extrudare prost calibrate și răcire neuniformă a fibrei și pot ajusta parametrii de extrudare și răcire pentru a elimina deșeurile. Astfel de echipamente avansate pot economisi între 10 și 15% din materiile prime comparativ cu echipamentele mai vechi. În plus, echipamentele mai avansate, precum cele oferite de Shenzhen Softgem, pot accepta o cantitate mare de materiale reciclate, cum ar fi sticle PET, ca materie primă pentru producție, reducând astfel și mai mult costurile de producție. Aceste materii prime sunt mai ieftine și mai prietenoase cu mediul în comparație cu cipurile virgin de PET, oferind astfel un dublu avantaj: economii de costuri și sustenabilitate.

Atunci când se prelucrează poliesterul, costurile energetice acumulate în timpul producției devin o cheltuială pe termen lung pentru producător. Costurile energetice vor deveni mai puțin oneroase cu ajutorul unei mașini de poliester eficiente din punct de vedere energetic. Mașinile vechi de poliester generează multe costuri energetice datorită încălzitoarelor ineficiente, încălzitoarelor învechite, motoarelor ineficiente și lipsei totale de recuperare a energiei, ceea ce reprezintă un motiv major pentru costurile energetice ridicate. Mașinile noi de poliester integrează tehnologii eficiente din punct de vedere energetic. Acestea dispun de încălzitoare cu recuperare de energie care captează căldura reziduală provenită din fazele de topire și uscare ale procesului și o folosesc pentru a încălzi materiile prime și atelierele de producție, economisind astfel 20-30% din energie în timpul procesului. De asemenea, au motoare de înaltă eficiență care fac ca funcționarea în gol și evitarea risipei de energie să fie cât mai eficiente. Este vizată și pierderea de energie cauzată de izolarea slabă a camerei de topire. Mașinile optimizate energetic fabricate de Shenzhen Softgem ajută producătorii să respecte reglementările de mediu, evitând astfel amenzi pentru nerespectarea acestora, reducând în același timp costurile energetice.

Una dintre principalele cheltuieli în producerea poliesterului o reprezintă costul forței de muncă, deoarece o mașină de poliester minimizează utilizarea muncii manuale prin automatizare. Tradițional, o mașină de poliester necesita mult personal pentru gestionarea alimentării cu materii prime, ajustarea parametrilor mașinii, controlul calității și sortarea produselor finite. Aceasta ducea la creșterea costurilor cu forța de muncă și la expunerea la erori umane. Astăzi, mașinile de poliester au integrat automatizarea majorității acestor sarcini, iar sistemul de automatizare al mașinii de poliester poate fi gestionat printr-o consolă centralizată automat. Acest lucru permite unui singur operator să supravegheze mai multe ansambluri ale mașinii, reducând astfel numărul de angajați cu 60-70%. Aceasta reduce nu doar costurile cu forța de muncă, ci și costurile asociate cu instruirea, securitatea socială și managementul resurselor umane. Mașina de poliester fabricată de Shenzhen Softgem include un sistem automat de diagnosticare a defecțiunilor, care reduce, de asemenea, costurile de management al instruirii.

Pierderile de producție, costurile crescute și opririle neprogramate datorate întreținerii frecvente pot fi costisitoare. Fără îndoială, o mașină de poliester de înaltă calitate reduce costurile legate de pierderile de producție și ajută la evitarea opririlor neprogramate prin performanța sa fiabilă și funcțiile de întreținere predictivă. În primul rând, proiectarea de înaltă calitate, fără întreținere, a mașinii de poliester și construcția durabilă cu componente rezistente la uzură conduc la prelungirea duratei de viață, înlocuirea mai rară a conductelor fără coroziune și utilizarea unor rulmenți de înaltă calitate. În al doilea rând, sistemele de întreținere predictivă fac parte din modelele avansate de mașini de poliester. Sistemele predictive, echipate cu senzori și colectare de date, permit monitorizarea în timp real a stării componentelor mașinii și controlul predictiv al acestora. De exemplu, dacă sistemul de control predictiv al secțiunii de tragere a unei mașini de poliester detectează o problemă și trimite alerte, echipele de întreținere pot înlocui rulmentul în timpul opririi programate. Spre deosebire de sistemele tradiționale, acest model de întreținere predictivă poate reduce opririle neprogramate cu 30-40% și poate diminua costurile de întreținere de urgență. În plus, sistemele Softgem pentru productivitate sporită reduc costurile de întreținere cauzate de opriri și pierderile de producție.

Știri Populare

Știri Populare2024-07-25

2024-07-25

2024-07-25