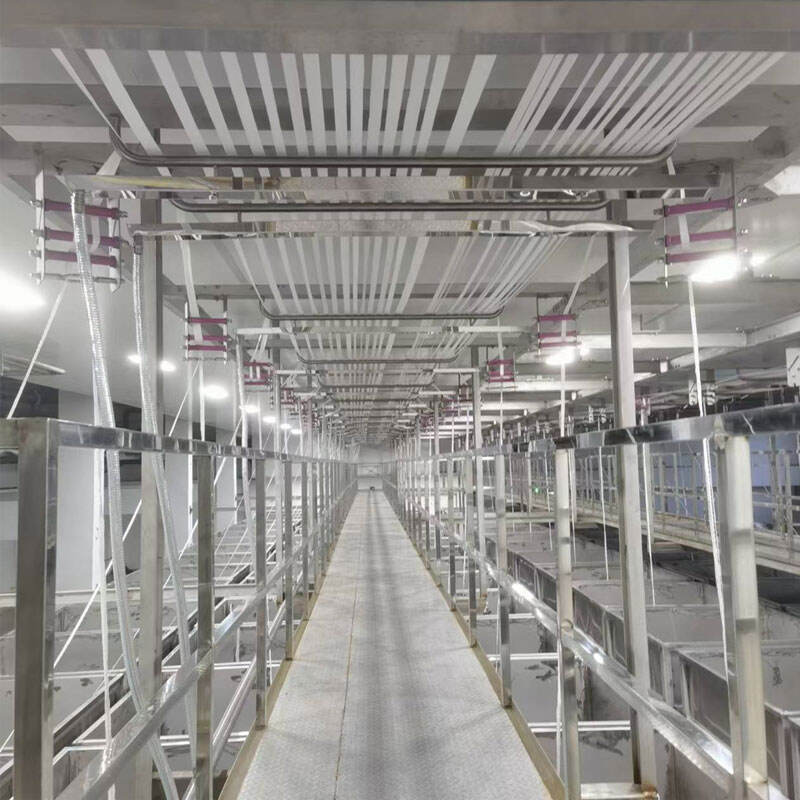

At Suzhou Soft Gem Intelligent Equipment Co., Ltd., we have streamlined processes with energy effective bottle spinning to produce exquisite fiber material. Our processes save energy and improve production speeds. Integrating intelligent and energy efficient manufacturing systems and processes, we make sure our systems and solutions attain optimal performance and eco-friendly results. Our dedicated and skilled personnel develop system solutions to help our global customers grow and develop to meet the diversified and competitive needs in the marketplace.