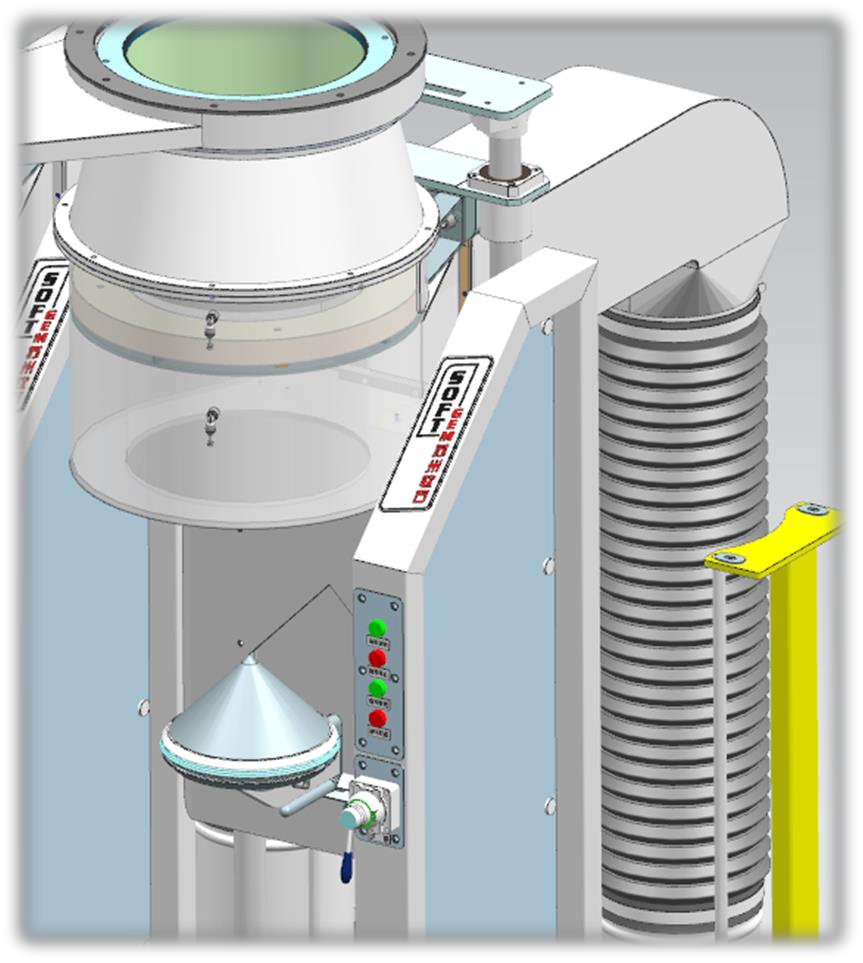

يجب إدارة كل مرحلة من مراحل عملية إنتاج ألياف البوليستر (PSF)، بما في ذلك البلمرة، والغزل، والقطع، بشكل فعال. في شركة سوتشو سوفت جيم للتجهيزات الذكية المحدودة، نحن نحرص بعناية على كل مرحلة لدعم الإنتاجية والجودة. تتيح لنا تقنياتنا المتطورة معالجة وإدارة مواصفات الألياف المختلفة، مما يحافظ على مرونة وتنوع الإنتاج. وفي إطار السعي إلى تحقيق أقصى قدر من تبسيط العمليات وأتمتتها لتوفير التكاليف، فإننا نُطبّق تقنيات رقابة رقمية متطورة على العمليات.