The pet fiber machine has long been a key tool in making the fibers we use every day—from clothes to home textiles. But in recent years, this machine isn’t just doing the same old job. New innovations are making pet fiber machine faster, greener, and smarter, helping factories keep up with demand while cutting costs. Whether it’s better materials for the machine or new tech that monitors every step, these changes are reshaping how we make PET fiber. Let’s break down the top innovations that are transforming pet fiber machine technology right now.

Smart Automation and Real Time Monitoring

One of the biggest shifts in pet fiber machine tech is the move to smart automation. Gone are the days when workers had to stand by the machine nonstop, checking every detail by hand. Now, many pet fiber machine models come with sensors that track things like temperature, material flow, and fiber thickness in real time. If something goes off track—like the temperature getting too high—the machine adjusts itself automatically. This not only reduces mistakes but also makes the pet fiber machine run more smoothly. Some advanced pet fiber machine even connects to smart systems that collect data over time, helping factories spot ways to improve efficiency. For example, a pet fiber machine with 5G integration can send data to a central hub, so managers can keep an eye on production from anywhere. This kind of automation isn’t just about making work easier; it’s about making the pet fiber machine more reliable and productive.

Green Tech for Lower Energy Use and Waste

More and more, pet fiber machine are going green—and it’s not just for show. Factories are looking for ways to cut energy costs and reduce waste, and new pet fiber machine designs are delivering on that. Many modern pet fiber machine use special motors that save electricity, and some even have heat recovery systems that reuse energy from the machine instead of letting it go to waste. Another big green innovation is the ability to process recycled materials. Today’s pet fiber machine can take old PET bottles or textile scraps and turn them into high quality fiber, skipping steps that used to waste energy. For instance, some pet fiber machine now skip the “chip making” phase, which cuts down on both energy use and plastic waste. This not only helps the planet but also saves factories money on raw materials and energy bills.

Flexible Designs for Multiple Fiber Types

In the past, a pet fiber machine could usually only make one type of fiber—like solid or hollow. But now, thanks to flexible designs, a single pet fiber machine can switch between making different kinds of PET fiber without big overhauls. This is a game changer for factories that need to keep up with changing market demands. For example, some pet fiber machine can make everything from thin fibers for masks to thick fibers for carpets, just by adjusting a few settings. This flexibility means factories don’t need to buy separate machines for each product, saving space and money. Companies like Suzhou Soft Gem even offer pet fiber machine that can handle both bio component fibers and degradable PLA fibers, making it easy for factories to expand their product lines. This kind of versatility is making the pet fiber machine a more valuable tool for businesses.

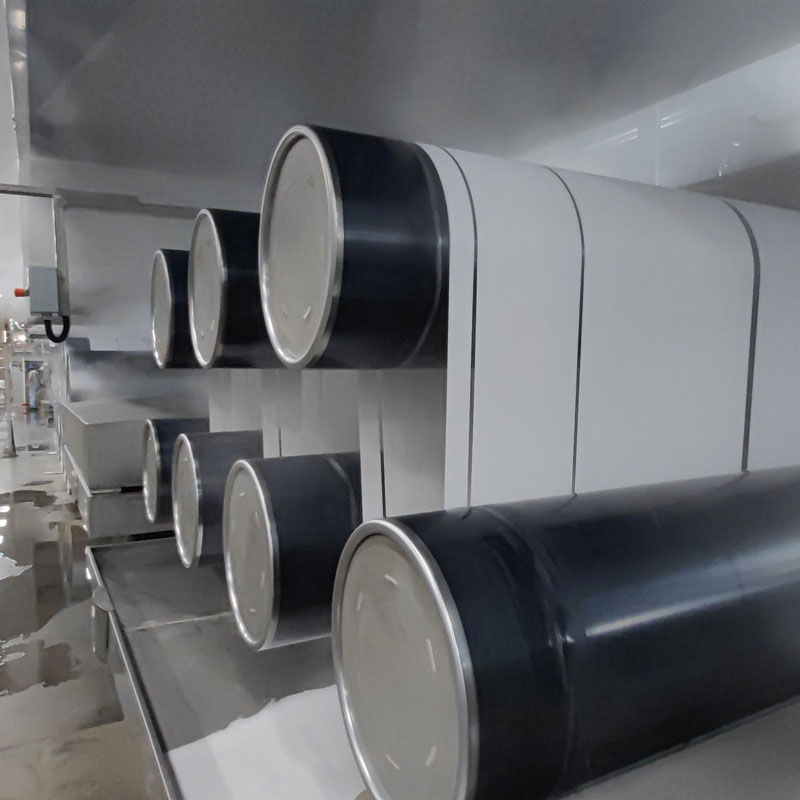

Advanced Material and Component Upgrades

The parts that go into a pet fiber machine are getting better too, and that’s making the whole machine work smarter. For example, the screws in many new pet fiber machine are made from high strength alloy steel, which is more durable and melts materials more evenly. This means the pet fiber machine can run longer without needing repairs, and the fiber it makes is more consistent. The nozzles (called spinnerets) in the pet fiber machine are also getting upgrades—some now have finer holes that make ultra thin fibers, perfect for medical masks or high end clothing. Even small parts like filters are improving; new filters in the pet fiber machine catch more impurities, so the fiber stays clean and high quality. These material upgrades don’t just make the pet fiber machine last longer—they also help it make better fiber in less time.

Full Life Cycle Services and Turnkey Solutions

Finally, the way we support and set up pet fiber machine is changing for the better. It’s no longer just about selling the machine—now, companies offer full life cycle services to keep the pet fiber machine running smoothly. For example, Suzhou Soft Gem provides everything from helping factories design the right layout for their pet fiber machine to training workers on how to use it, and even maintaining the machine later. This turnkey approach means factories don’t have to piece together solutions from different places. It also ensures that the pet fiber machine is set up correctly from day one, so there’s less downtime. Some companies even offer remote support for pet fiber machine—if there’s a problem, technicians can fix it from afar using digital tools. This kind of support makes the pet fiber machine more reliable and gives factories peace of mind.

Hot News

Hot News