Industries today—be it textiles, healthcare, automotive, or filtration—require materials that combine efficiency, versatility, and functionality. Bicomponent fiber, which involves melding two distinct polymers to yield fiber that combines two different polymers, stands out as an answer to this challenge. Bicomponent fibers, unlike conventional single-component fibers, integrate the functionality of two different components. This multifaceted functionality, as opposed to the simpler single-component fibers, helps in innovation across different industries. This blog discusses how bicomponent fiber caters to the needs of the current industries, Its advancement in the application of fiber and technology, its positive impacts in the sustainability efforts, and the contribution it makes to social developments. This is to emphasize the indispensable wiring of bicomponent fibers in the advancement of industries.

First of all, industry-oriented composite fibers provide different performance solutions to the most underlying problems an industry faces. Traditional fibers compel an industry to take a compromise. One may use a fiber that is strong and loses breathability or loses softness and breathability and becomes pliable and soft. Bicomponent fibers are crafted to remove these compromises as two polymers of different properties are coupled. For inclusion, stronger and more resilient (dry) polymers like polyester and polyethylene can be coupled to make a fiber that is suitable for moisture management (active wear) as well as breathable.

In the medical field, the combination of biocompatible polypropylene and elastic polyurethane materials for surgical masks and wound dressings is an example of comfort and stretch attributes. The ability of bicomponent fibers to combine differing obligations results in the ability to create multi-functional fibers. These innovations enable industries to surpass the rigorous benchmarks previously set for single-component fibers.

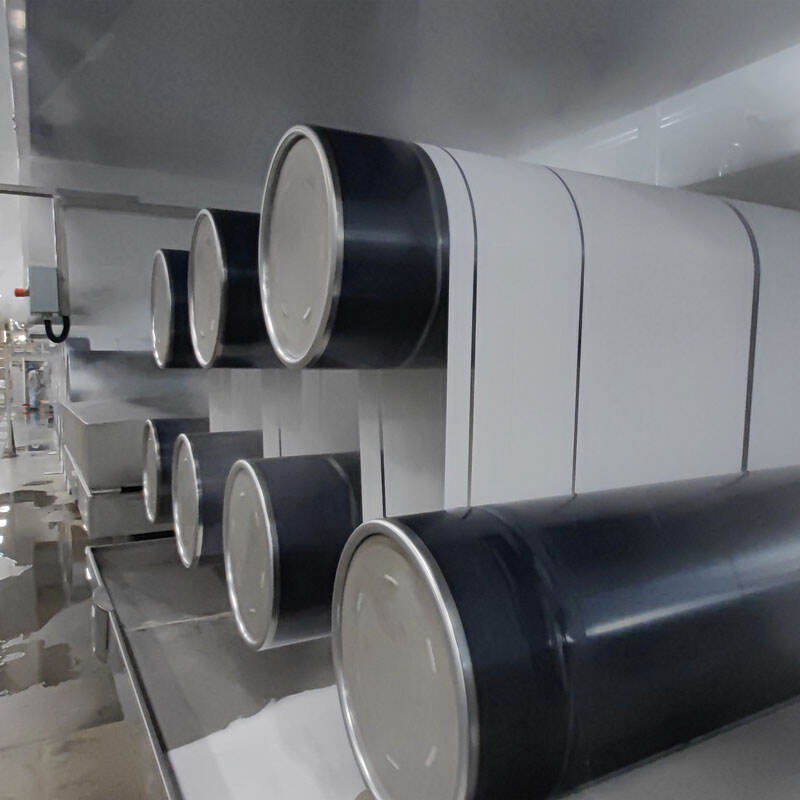

The wide application range for bicomponent fibers makes them pivotal for the modern interconnected industry, driven by the diverse needs of disparate sectors. Unlike single-use specialized materials, bicomponent fibers balance multiple applications across textiles for moisture-wicking apparel and anti-pilling finishes, high-efficiency air and water filters, lightweight and sound-dampening automotive interiors, and non-woven diaper and medical gown fabrics in healthcare. Consider core-sheath structured bicomponent fiber that can be engineered to provide super absorbent properties in baby diapers and capture fine particles in industrial filters. The ability to serve diverse applications with core bicomponent fibers perpendicular to industry standards streamlines supply chains.

Cost-effective production and improved industrial efficiency and profitability make bicomponent fiber important for the industry. Though specialized equipment for bicomponent fiber production may be necessary for initial setup, the unique structure of the fiber allows downstream processing to be less complicated. For example, certain bicomponent fibers can be microfibers mechanically or chemically treated, which eliminates the need for costly microfiber production spinning equipment, thus reducing spinning costs by 20–30%. In the non-woven industry, the energy costs of fabric formation are reduced because bicomponent fiber can be bonded at low temperatures. Moreover, the durability of the bicomponent fibers means that the end products last longer, which, for many industries, reduces the replacement frequency of products. For instance, the bicomponent fiber used in the automotive industry doubles the life of the interior upholstery, thus reducing the maintenance costs for automotive manufacturers. All these make the purchase of bicomponent fiber sensible for industries that need to improve profitability without negatively impacting the quality.

With sustainability in the industrial context becoming more important, the other reason the industry needs to focus on bicomponent fiber is that it helps in achieving environmental sustainability goals. There are two ways by which the bicomponent fiber achieves this: it can be produced with recycled polymers.

The production of bicomponent fibers can be achieved by combining recycled polyester (from plastic bottles) and bio-based PLA (polylactic acid) as they allow to use less virgin materials. Another reason why bicomponent fibers are more efficient is that less waste is produced in the manufacturing process. The traditional fiber manufacturing process is wasteful and generates excess scraps, while the bicomponent fiber's precise structure focuses on high material utilization (over 95% in most cases). In the packaging industry, the bicomponent fiber-based non-woven fabric can completely replace single-use plastic as it is biodegradable. Such sustainable features enable industries to respond to global environmental regulation such as the EU’s Circular Economy Action Plan and consumer demand, positioning bicomponent fiber as the foundation of green industrial practices.

Bicomponent fiber is essential for today’s industry because it drives innovation in high-tech sectors that shape the future. Industries like aerospace, electronics, and advanced manufacturing require materials with extreme performance—such as heat resistance, conductivity, or flame retardancy—and bicomponent fiber delivers on these needs. For example, in aerospace, a lightweight and fireproof component for aircraft's interior is produced by the use of a bicomponent fiber that consists of high strength carbon fiber and heat resistant ceramic. In electronics, a bicomponent fiber that combines insulating nylon and conductive copper is used to create flexible, wearable sensors for smart devices.

These cutting-edge applications benefit greatly from the unique characteristics of bicomponent fiber, which makes previously unachievable products possible. Many new technologies in cutting edge high tech industries would face considerable material challenges if they did not have bicomponent fibers. This would greatly hinder the pace of innovation in these industries.

Conclusion

The unique combination of versatile applications, affordable production, contribution to high-tech development, assistance with innovation, and variable performance combinations make bicomponent fiber instrumental in today’s industry. It addresses industry challenges and optimizes performance across textiles, healthcare, automotive, and other industries. As industries continue to push the boundaries with what they can do, the importance of bicomponent fibers in industrial development will continue to increase. For high quality bicomponent fibers for textiles, filtration, high-tech applications and other industrial needs visit https://www.szsoftgem.com/ to see the professional bicomponent fiber products and customized solutions we offer.

Hot News

Hot News2024-07-25

2024-07-25

2024-07-25