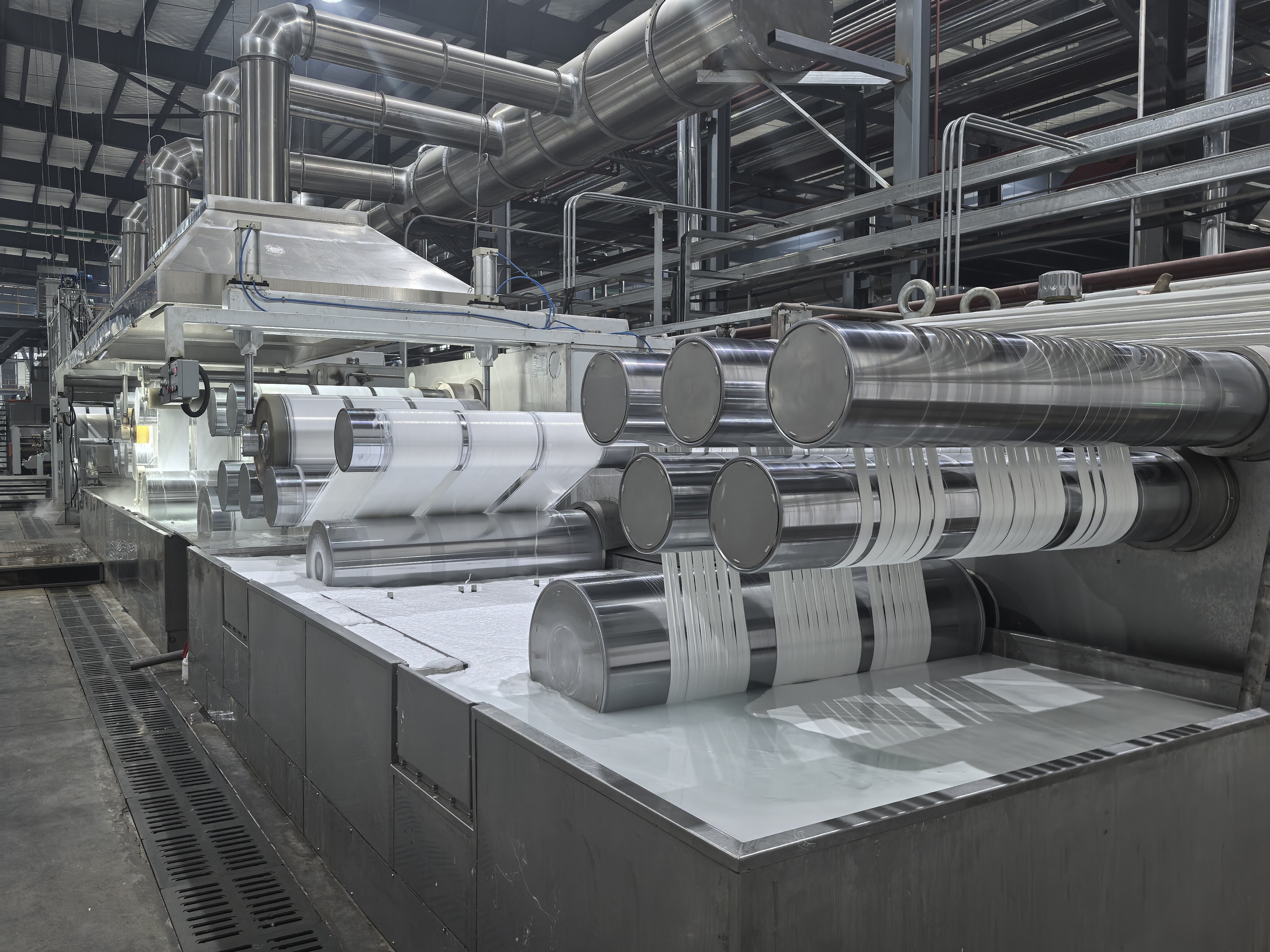

The integrated PSF production line offers simplified methods for producing polyester staple fiber, providing high-quality outcomes and minimizing waste. We automate and digitally integrate fiber production methods for automation real-time monitoring and automatic adjustments. We automate processes globally for efficiency, and lower energy use and emissions for sustainability. Our designers work directly with customers to customize production to specific needs as all production outcomes must meet desired product standards.